How to Choose the Right Gripper for Your Application

17 September 2025

Gripper Technology Overview: A Technical Guide

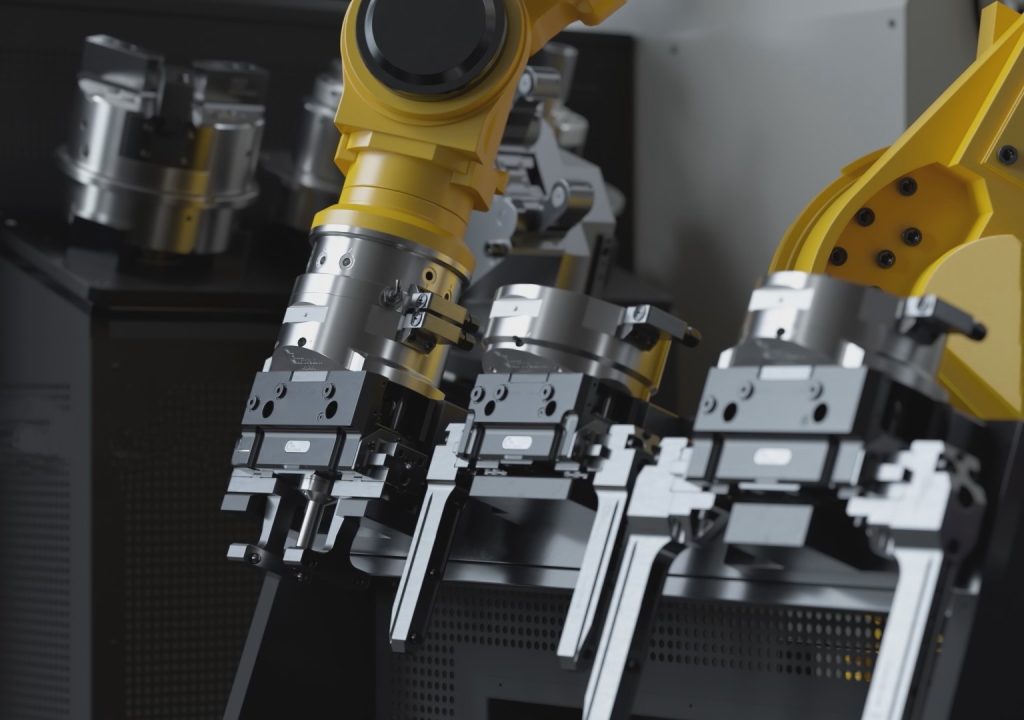

In manufacturing and automation, selecting the correct gripper is critical for

process reliability, part accuracy, and overall system productivity. The gripper is

often the first and last point of contact with the workpiece, making it one of the

most important decisions an engineer can make when specifying tooling. A poorly

matched gripper can cause slippage, part deformation, or downtime, while the

right choice ensures consistent performance and long-term ROI.

This guide presents the principal technical factors to evaluate in order to support

a systematic and well-informed decision-making process.

1. Define Part and Process Requirements

The workpiece itself dictates gripper selection. Begin by documenting:

Geometry: Flat, cylindrical, prismatic, or irregular parts require different

jaw/finger designs. Internal vs. external gripping must also be evaluated.

Mass and Inertia: Calculate the part weight and include a safety factor

(typically 2–3×) to account for acceleration and deceleration forces during

handling.

Surface Conditions: Smooth, oily, or coated surfaces may require textured or

serrated inserts to increase friction and reduce slippage.

Tolerance Sensitivity: Thin-walled or delicate parts must be gripped with

controlled force to avoid distortion. For precision machining, positioning

repeatability within microns is essential.

2. Gripping Force and Repeatability

Sizing the gripper properly prevents both under-clamping and part damage.

Force Calculation: Required gripping force = (part weight × acceleration

factor) × safety margin.

Dynamic Loads: Consider robot arm speed, orientation (vertical/horizontal),

and vibration from machining or transfer.

Delicate Components: Use adjustable-force grippers or softer contact inserts

to reduce localized stress.

Precision: For machining or gauging applications, look for grippers offering

<0.01 mm repeatability to maintain part accuracy.

3. Pneumatic vs. Mechatronic Grippers

Today’s two dominant gripper technologies each serve distinct roles.

Pneumatic Grippers

Advantages: Simple, fast, compact, and cost-effective.

Best for: High-volume production where part size and shape are consistent.

Considerations: Limited feedback and force control; requires stable

compressed air supply and filtration.

Mechatronic (Electric) Grippers

Advantages: Programmable force and stroke, integrated sensors, position

control, and data connectivity.

Best for: Flexible automation, lights-out machining, variable part families, and

applications requiring traceability.

Considerations: Higher initial investment but long-term gains in flexibility,

energy efficiency, and reduced air consumption.

4. System Integration and Connectivity

A gripper should integrate seamlessly with the rest of the automation cell.

Mounting Interfaces: Verify robot wrist or fixture compatibility. Standardized

quick-change systems simplify upgrades and service.

Feedback Options: IO-Link, force sensors, and position feedback enable

closed-loop control and real-time monitoring. This improves process reliability

and supports predictive maintenance.

Cycle Time: Evaluate open/close speed, actuation time, and energy use.

Over thousands of cycles, even milliseconds can affect throughput.

5. Flexibility and Changeovers

Most manufacturers handle multiple parts, so flexibility is key.

Modular Finger Designs: Quick-change fingers allow fast reconfiguration

without full gripper replacement.

Adaptive Systems: Mechatronic grippers can store multiple grip profiles,

automatically adjusting stroke and force for different parts.

Standardization: Using common gripper interfaces across machines reduces

spare part inventory and training requirements.

6. Environment and Operating Conditions

The environment in which a gripper operates can dictate material and design

choices.

Coolant, Oil, or Dust: Sealed pneumatic grippers or IP-rated mechatronic

units extend service life.

Temperature Extremes: Check gripper specifications for high-heat machining

or cold storage applications.

Maintenance Access: Plan for easy replacement of wear parts like seals,

inserts, or jaws to minimize downtime.

Final Engineering Takeaway

The optimal gripper depends on the specific application. Pneumatic grippers

excel in speed and cost-efficiency for stable, repetitive tasks. Mechatronic

grippers deliver unmatched flexibility, feedback, and adaptability for high-mix,

automated environments.

Engineers should always size for reliability, not just minimum requirements, while

considering force, precision, connectivity, and future flexibility. By treating gripper selection

as a structured engineering process, you can maximize productivity, reduce risk,

and future-proof your automation systems.

Download the .pdf here or, download the .pdf file below. ⬇️

DOWNLOAD ATTACHMENT