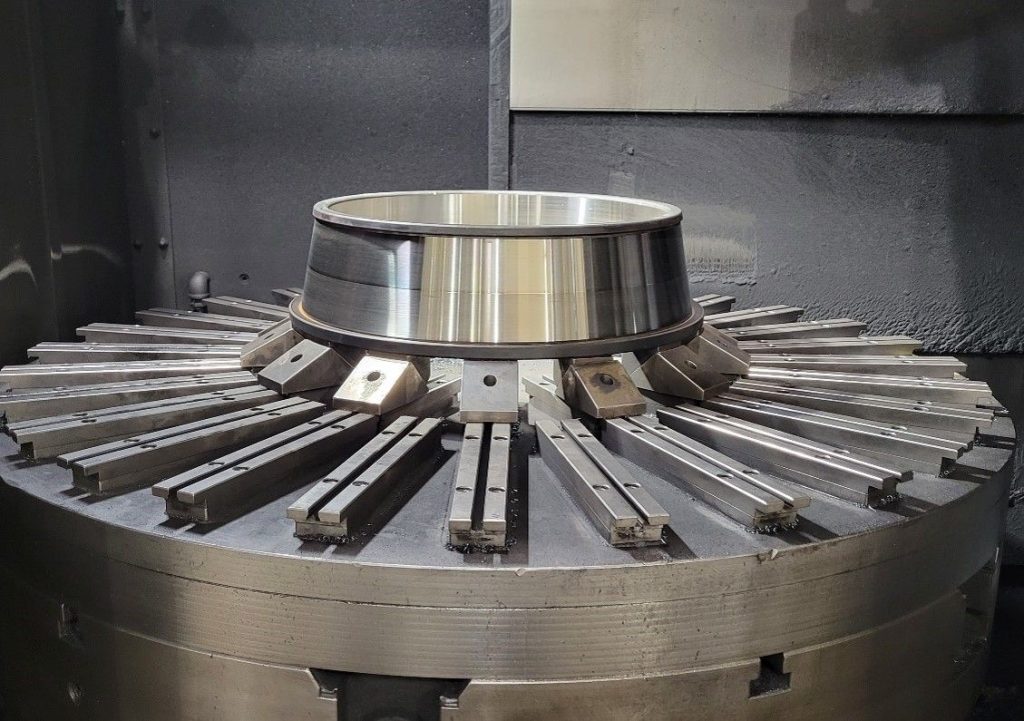

Introducing the Radial Pole Magnetic Chuck for Vertical Turning and Grinding

20 June 2023

Wheeling, IL – The Radial Pole permanent electromagnetic system is used for vertical turning and grinding of thin wall parts such as bearings, rings, gears, and flanges. Unique to this magnetic system is that when using three solid pole extensions, and using the remainder with spring-loaded pole extensions, this allows the chuck to clamp workpieces with non-distortional clamping from the base surface. Therefore, there are no obstacles to the tool path for three sides of the part and no deformation which does occur with mechanical clamping. Parts can be machined with extremely high accuracies of 10 to 20 microns which can in many cases eliminate grinding.

Since users are holding the part for the base, setups are dramatically reduced. Pole extensions allow users to raise the piece from the magnet surface making the top, inner and outer diameters fully machinable. This process dramatically reduces part distortion due to clamping with ZERO distortion and allowing for far more accurate part processing.

Additional features of the Radial Pole Magnetic Chuck include:

- Full use of machine table

- Complete machining operation in a single setup

- Automatic shimming for stress free operation

SMW Autoblok’s magnetic products also include a full line of permanent electromagnetic chucking systems for quick and flexible workholding on horizontal and vertical milling machines, vertical turning centers, FMS systems, grinding machines, EDM’s, etc. A full line of magnetic lifters for loading and unloading workpieces is also offered