SMW-AUTOBLOK showcases its extensive portfolio of gripping systems at Automatica

30 May 2023

Moving Innovations for Process Automation

(PresseBox) (Meckenbeuren, 30 May 2023)

SMW-AUTOBLOK now offers its customers a complete portfolio of mechatronic and pneumatic gripping systems, along with a wide range of accessories for the digitalization and automation of processes. A particular highlight is the manufacturer’s inductive coupling systems. This innovative technology enables contactless energy and signal transmission, making it especially suitable for use in EOAT (End of Arm Tooling) automation.

“By combining mechanics, electronics, and software, we have transformed ourselves from a traditional clamping device manufacturer into a high-tech process solutions provider,” explains Eckhard Maurer, Managing Director of SMW-AUTOBLOK Spannsysteme GmbH, Meckenbeuren. “We have expanded the product areas of mechatronics, contactless transmission technology, sensor systems, and software, bundling them in our new company, SMW-electronics GmbH, to generate further synergies.”

SMW-AUTOBLOK will demonstrate the potential of this innovative product and technology portfolio for process automation at the Automatica trade fair in Munich from 27 to 30 June. Among the highlights will be their mechatronic grippers from the MOTIACT series. This range reliably covers motion tasks of all sizes with its small-part grippers MX-S, universal grippers MX-M, and long-stroke grippers MX-L. All MOTIACT grippers are equipped with an incremental measurement system to monitor grip position, and their gripping force is independent of gripping speed and stroke. Each model in the MOTIACT series offers IO-Link/Ethernet interfaces and is protected according to IP67 standards (MX-S: IP40). A high-speed variant for the MX-S is currently in development.

With the MX-L 520, SMW-AUTOBLOK provides a mechatronic long-stroke gripper designed for high-performance applications. It delivers maximum flexibility and safety, with gripping forces ranging from 10 to 40 kN, large jaw strokes, pre-positioning, and adjustable clamping force — and ensures grip force retention even in the event of a power failure. Each jaw offers a maximum stroke of 99 mm, with repeatability of plus/minus 0.02 mm.

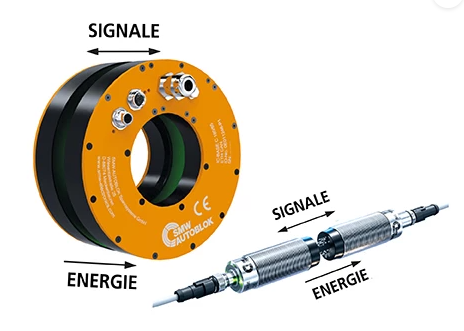

Inductive Coupling System Enables 360° Rotation

Using SMW’s inductive coupling system, all MOTIACT grippers can achieve 360° rotation in both directions. This advanced technology for contactless energy and signal transmission provides numerous additional benefits: the couplers allow a flexible installation with transmission distances of up to 5 mm. Signal transmission between the control system and the gripper occurs contactlessly through an integrated interface and is unaffected by the rotation of the mobile unit, vibrations, or high speeds. Data transmission is even possible through non-metallic obstacles. Additionally, the stationary base unit of the coupler can communicate with multiple mobile units if required (dynamic pairing).

Combined with an inductive coupler, the MOTIACT grippers are ideal for EOAT (End of Arm Tooling) applications. Users benefit from a comprehensive, flexible product portfolio that can be adapted to a wide variety of motion tasks.

Interested users will have the opportunity to meet SMW-AUTOBLOK from 27 to 30 June at automatica 2023 in Hall A5, Booth 121.